Work begins in the lab on UX-1: Part 1 – Tampere University of Technology

The UNEXMIN project is now in its second year. After the first year, where work mainly focussed on preparatory tasks such as research and component-design, the project is now entering its most important phase prior to testing. During this phase, the custom-designed casing and instrumentation hardware will be manufactured and assembled to create the first UX-1 robotic prototype, which is due in the beginning of 2018.

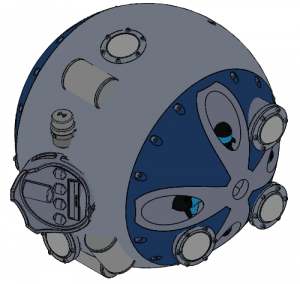

General layout of the future UX-1 robot

Like much of the work done in the previous year, the majority of the workload in the coming months will be centred in the labs of some of the project’s partners, including TUT (Tampere University of Technology), UNIM (University of Miskolc), UPM (Universidad Politécnica de Madrid), INESC TEC (Instituto de Engenharia de Sistemas e Computadores, Tecnologia e Ciência), and RCI (Resources Computing International).

Hands-on lab-work is essential in UNEXMIN, where we are creating a new technology that will be capable of autonomously exploring and mapping flooded mines. For the success of the project, our team has to continually conduct research and testing and implement necessary modifications. Everything must be optimised and fine-tuned if all the equipment, such as the on-board computer, batteries, and thrusters, is to fit inside the spherical robotic prototype.

The work of TUT (Tampere University of Technology), one of the project’s leading partners, is mainly centred on the development of the robotics components of UX-1. TUT are responsible for a total of 10 predefined deliverables including ‘Robotic Platform Prototype requirement specifications‘, ‘Robotic Platform Prototype technical and mission specifications‘, and ‘Stakeholder-requirement specifications‘. Among their various other responsibilities, these deliverables are essential for the development of the robotic prototype and the definition of its available services.

The TUT team preparing the UX-1 plastic mock-up for a stability test

A demonstration of TUT’s implemented UX-1 remote-operation capabilities

Since the beginning of the project, Jussi Aaltonen‘s team at TUT have been working on the definition of the robotics specifications that will serve has the base for construction the UX-1 prototypes. To date, TUT have designed and tested key robotics features necessary for implementation in flooded underground mines. TUT’s activities have included pool tests at their testing pool using a plastic mock-up of UX-1, functionality testing of robotics equipment in the laboratory, and also software and hardware testing.

A UX-1 plastic mock-up

The TUT team is currently finalising the technical specifications and mechanical design of the prototype, as well as building the pressure hull that will support the internal components of the robotics system. Fabrication of the pressure hull components will begin shortly, once the final mechanical analyses are complete. The first UX-1 prototype will be ready at the beginning of 2018!