Work begins in the lab on UX-1: Part 2 – University of Miskolc

In one of the latest posts on UNEXMIN, it was presented the work being done by TUT. Now it’s time for another team of the UNEXMIN’s consortium.

The UNIM team comes from the University of Miskolc, Hungary. They are responsible for Work Package 2 “Scientific instrument design and adaptation” and are working one of the most important areas for the future multi-robotic system – building tailor-made instruments that will allow the robot to get the most meaningful geoscientific data possible inside flooded mines.

Many of the spaces designed for the UX-1 submersible will be filled with scientific instruments developed by UNIM

Inside Work Package 2, UNIM is responsible for deliverables such as the “Parameter framework report”, “General interface specification report”, “Laboratory test reports of instrumentation units” and “Real environment test report of instrumentation units”. In short, UNIM has been studying and developing the scientific instruments while testing them in the laboratory and in field conditions. These steps will guarantee that the scientific components work at maximum efficiency in flooded mine environments (confined places, pressure and temperature constraints, etc).

UNIM team testing the scientific instrumentation in the field (Rudabánya open-pit mine)

UNIM’s work, which started right in the beginning of the project, can, in a nutshell, be described as defining, adapting, testing and calibrating the various scientific instruments (see the list below) that the UX-1 robot will carry on board during its missions. The scientific instrumentation was carefully chosen: the consortium had to evaluate considerations from the project stakeholders in what they wanted in the robotic system (user requirements) and various constraints related to the prototype design (i.e. size and weight limitations). These important factors limit the amount of equipment available for the robotic system.

The list of scientific apparatus include:

- pH unit

- Electrical conductivity analyser

- Pressure and temperature analyser

- Water Sampler

- Magnetic field measurer

- Gamma-ray meter

- Sub-bottom profiler

- Multispectral camera

- UV fluorescence unit

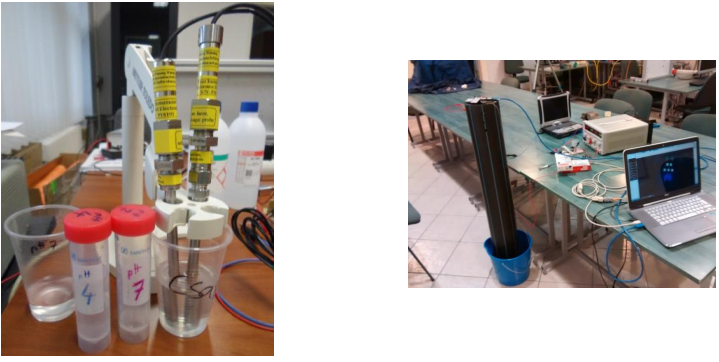

Some of the scientific equipment being tested. On the left: Test equipment for pH ; On the right: Underwater test equipment for UV lighting

The instrumentation listed above can be divided into Water sampling methods (including pH, electrical conductivity, pressure and temperature measurements), Geophysical methods (including Magnetic field, Gamma-ray, Sub-bottom profile measurements) and mineralogical – or optical – methods (including multispectral camera and UV fluorescence measurements). These methods will substitute the impossibility to use direct methods like collect rock samples from mining walls, thus allowing the robot to still get valuable nonscientific data. In a project of this nature, valuable data is everything.

The results of the work being developed by UNIM will be seen when the first robotic prototype UX-1 is ready to be tested in early 2018 – the first test is scheduled for May, in the Kaatiala Mine, Finland.