Posts

Summary of the second week of field work at the Ecton mine, UK

/in Field trials, News/by Luis LopesThe UNEXMIN’s Ecton field mission that officially started on the 13th of May, will run until the 31st. After the exploration efforts made during the first week (from 13 to 19 May), that provided some interesting results on the flooded mine workings, such as shafts and galleries being mapped, the second week of trials is now surpassed. The most relevant aspects of this week were:

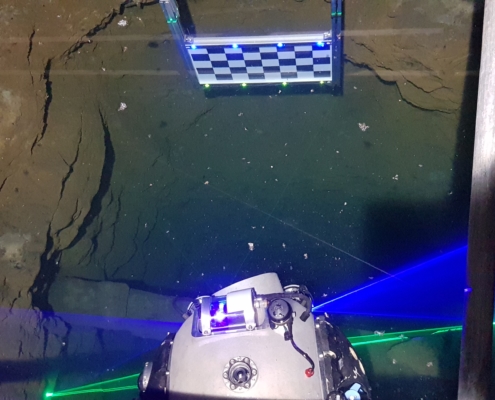

- 20th of May (Monday): The first dive of the second week was quite successful: UX-1 dived around to 92m without major problems. John Barnatt, EMET’s archeologist, managed to get information on parts of the mine that he thought did not even to exist! Also, past mining heritage, including wooden support structures were identified.

- 21st of May (Tuesday): One dive was made with the UX-1 robot during this day. A depth of 54m meters down the Great shaft was reached. Similarly to the past day, both geological and archeological items of relevance were identified with the help of images provided by the many UX-1’s cameras.

- 22nd of May (Wednesday): Day dedicated to adjustments and small repairs on the robots. Part of the UNEXMIN team had a guided visit to another mine near Ecton – the Clayton mine. Similarly to Ecton, Clayton mine was operated in the past and is now closed and partly flooded. Perhaps another site for the UNEXMIN exploratory technology?

- 23rd of May (Thursday): A simple test dive with the robots was performed to assure the operability of the robots after the past-day improvements and repairs.

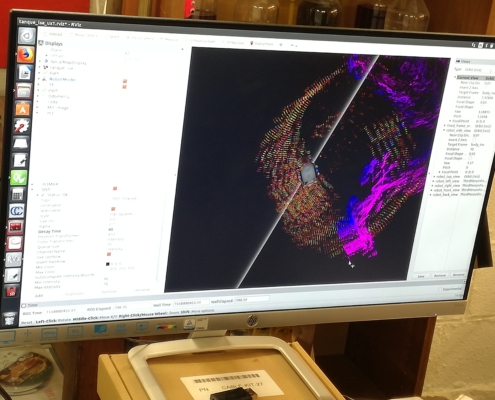

- 24th of May (Friday): The UX-1a robot once again dived within the Main shaft up to around 94m. Around the mark of 52m depth, the team of UNEXMIN geologists managed to visually identify some interesting mineralogy, quite different from the surroundings – a patch of green minerals (thought to be of malachite). Further identification is only possible with the use of the multispectral camera, which the UX-1 robot will do.

- 25th of May (Saturday): First dive with the UX-1b robot during the second week. Due to this reason and for guaranteed security of operations the robot only dived up to the 59m mark. Once again the patch of green minerals was seen on camera. Other geological structures such as stockworks were also identified by the geologists’ team.

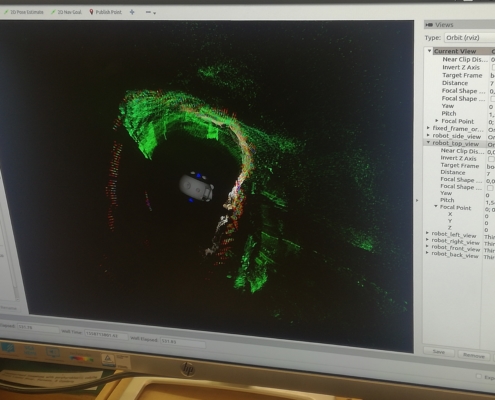

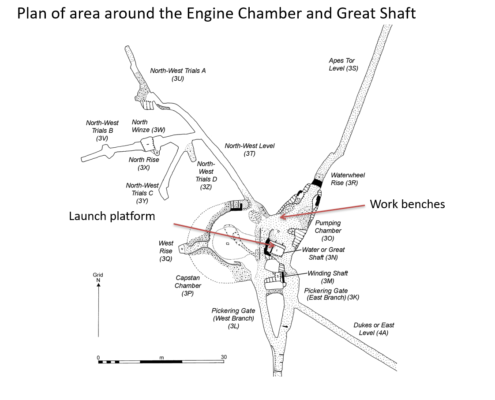

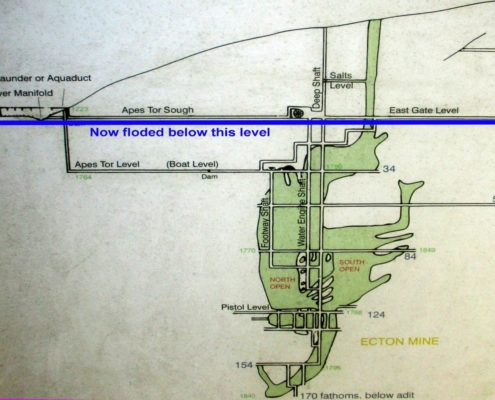

- 26th of May (Sunday): During the last dive of the second week the UX-1b robot managed to dive until the deepest point reached since the beginning of trials at the Ecton mine – 125m! The robot went down through the Main shaft, passed by two main intersections with other mining structures and managed to navigate around an area where an intersection between two shafts is seen. On the way up, the UX-1 robot collected some water samples, that will be later analysed in laboratory to learn more about the water chemistry at the flooded shaft.

After a successful second week, where the team met its major objectives – depths reached, areas mapped, discoveries made -, UNEXMIN is now proceeding with its last days in the UK. The aim is to reach even deeper and explore more flooded tunnels and galleries in a mine that has not been seen for the last 160 years… until UX-1 arrived!

Follow @UNEXMIN on our social media channels to keep up with the most recent news on the Ecton field trials: Facebook, Twitter and LinkedIn.

Summary of the first week of field work at the Ecton mine, UK

/in Field trials, News/by Luis LopesThe UNEXMIN team is in the UK, at the Ecton mines, to once again test its innovative exploration technology in real life conditions, after the field tests at Kaatiala, Idrija and Urgeiriça mines. The final aim of this trial is to map the most important flooded sections of the underground mine, at the same time as the team improves the operability of the surveying process. The first week on the field with the UX-1 robot was as follows:

- 13th of May (Monday): The first week of trials officially started on Monday, after a week of preliminary setups. The UNEXMIN team did some basic workings on both UX-1a and UX-1b robots. This was needed in order to have the robots ready for diving. All instruments and components of the robot were checked and repaired where needed.

- 14th to 16th of May (Tuesday to Thursday): Doing work on both the UX-1 robots, the control cabin with setting up connections between this and the work station inside the mine. Due to unexpected conditions, work got generally delayed, and the first official dive with the UX-1 robot only happened on Friday. Durind these days, the team strenghtened the operability of the robot, even without dives.

- 17th of May (Friday): The first dive with UX-1 was then done on this day. During this dive, the robot went up to a depth of 60m, through the Pumping shaft (also know as Great shaft). This was a highly successful dive: a lot of previously unrecorded geology and archeology was gathered from UX-1’s instrumentation. The UNEXMIN team found a big, interesting revelation at 58m: a very wide opening was identified, from which, EMET’s archeologist John Barnatt, believes to be a branch of the main mineral pipe – unexpected in that position.

- 18th of May (Saturday): Similarly to the Friday, the UX-1 robot descended until the 60m mark through the same shaft. This time, the main purpose was to test the robot capabilities such as movement, control and rapid descent. Most of the dive was achieved “nose down”, where the UX-1 robot moves with its front pointing downwards in a very challenging way.

- Sunday 19th (Sunday): Day-off dedicated to sighseeing around the Peak District. This area is known for its lead deposits in counterpart with Ecton, which is known for its copper deposits, quite unique in this geological area.

Follow @UNEXMIN on our social media channels to keep up with the most recent news on the Ecton field trials: Facebook, Twitter and LinkedIn.

The Ecton field trials have finally started!

/in Developments, Field trials, News/by Luis LopesThe beginning of the Ecton trials marks the fourth time that the UNEXMIN team will be on the field with the UX-1 robots to explore Europe’s flooded mines. At Ecton, the UNEXMIN team aims at exploring and mapping the entire flooded part of the underground mine workings with its innovative system. The UX-1 robots will be able to show light on the status and layout of a mine that no one has seen for more than 160 years! The Ecton field trials run from the 13th to the 31st of May.

Before the actual field trials, preparatory workings were held last week in order to guarantee that the Ecton trials go as smooth as possible. With all the practicalities set up, the UNEXMIN technical teams – TUT, UPM, INESC TEC, RCI and UNIM – are now ready to have the UX-1 system to recover geological, mineralogical and spatial information from deep Ecton during the next three weeks. Together with the technical teams a group of geological experts from the project will give specific input to geological and mineralogical identification.

The Ecton Mine Education Trust, partners in UNEXMIN and representing an important spectra of stakeholders – the cultural heritage side -, are collaborating with the other partners to assure that the trials are a success. With the data collected by the UX-1 technology, EMET expects to gain knowledge and uncover a precious part of the mine’s past in the form of its long-lost mining heritage (such as mining instruments used in the past). EMET, with the help of UNEXMIN, can then use these data for education and cultural purposes, benefiting the society at large. Achieving this will also prove the operability of the UX-1 technology in very challenging conditions and, at the same time, its usefulness.

Ecton will be the home of UNEXMIN for the rest of May. The team will work hard to have its robotic system explore and map all the flooded tunnels and galleries of this mine, attempting an increadibly challenging task. Fingers crossed!

Follow @UNEXMIN on our social media channels to keep up with the most recent news on the Ecton field trials: Facebook, Twitter and LinkedIn.

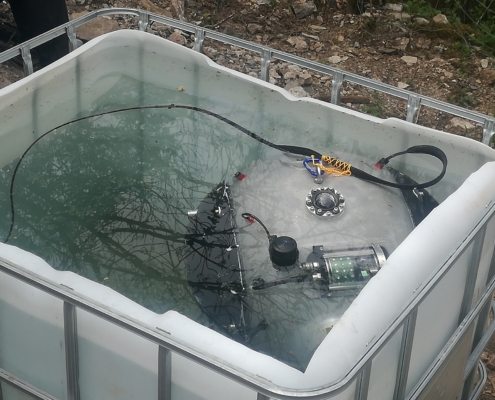

Preparations for the Ecton trial are on the way

/in Developments, Field trials, News/by Luis LopesThe UNEXMIN team, ahead of the official start of the 4th field trial, at the Ecton mine, in the UK, have just started with the preliminary preparations to host the most challenging surveying case within the project. These workings are needed in order to guarantee easy accessibility and operation of the robotic system and the UNEXMIN personnel during the trials, both inside and outside the mine. These include power cable installlation, telephone links from the surface to the mine’s interior, a comfort cabin and storage containers. The control cabin, from where the UNEXMIN team monitor operations, will also be set on site. Together with practical preparations, the team is also ensuring that all the must health and safety procedures are followed.

The preparatory workings will run until the 10th of May, with the actual field trials starting out on the 13th. The UNEXMIN project will count with most of its robotic system’s technology developers during the Ecton trials, with some of them (TUT, INESC TEC and UNIM) already on their way to the UK.

The main aim of the trials at the Ecton underground mine is to explore and map the entire flooded section with the UX-1 robotic system that nobody has seen for more than 160 years, after the mine closed and got flooded. The UNEXMIN technology will be able to collect and bring valuable geoscientific and spatial data that can be used by the local stakeholders – the Ecton Mine Educational Trust – for cultural and educational purposes. Surveying the entire flooded sections of the mine will, ultimately, prove the operability of the UX-1 system, in very challenging conditions – big extensions, great depths and difficult to navigate layouts.

Follow @UNEXMIN on our social media channels to keep up with the most recent news on the Ecton field trials: Facebook, Twitter and LinkedIn.

Recently on UNEXMIN…

- UNEXUP at EGU2020: Sharing Geoscience Online 11th May 2020

- UNEXUP e-meeting on “risk mitigation measures” 4th May 2020

- Technical Requirements of UNEXUP 21st April 2020

- Consortium e-meeting – Technical Requirements and Commercialization plan 30th March 2020

- Our first Press Release has been published! 16th March 2020

I want to know about…

Edit Babinszki

Edit Babinszki